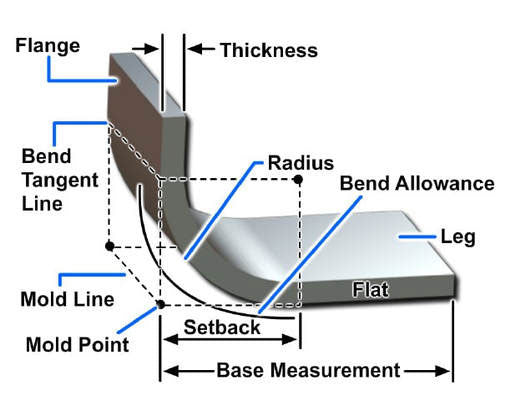

Before understanding the sheet metal setback, it is important to be familiar with the definitions of the mould line and bend line:

- The bend line refers to the straight line present on both sides of the bend plates and is located at the intersection of the bend area and the flange edge.

- The mold line refers to the straight line formed at the intersection of the outer surfaces of two bent flanges and can be either an outside or inside mold line.

Sheet metal setback refers to the distance from the bend line to the point where the metal starts to bend. It is also described as the difference between the mold line length and the flange length. Also is a crucial factor in sheet metal fabrication. In a 90-degree bend, the setback value is equal to the bend radius plus the thickness of the metal sheet.

By knowing the setback size, we can determine the bending tangent position of the workpiece. The setback plays a crucial role in workpiece design. If the workpiece needs to be bent multiple times, the setback must be subtracted for each bend.