Electromagnetic Sheet Metal Bender EB-6116, Magnetic Sheet Metal Brake, 1550mm Magnetic Panbrake Folder

Electromagnetic Sheet Metal Bender EB-6116, Magnetic Sheet Metal Brake, 1550mm Magnetic Panbrake Folder is backordered and will ship as soon as it is back in stock.

Couldn't load pickup availability

Delivery and Shipping

Delivery and Shipping

Standard freight charges do NOT include lifting off (unloading) from transport delivery vehicles where the total weight of goods exceeds 50kg, If you are unable to provide appropriate lifting please contact us for a quote on delivery that includes unloading.

Regional Australia address many need extra shipping cost

Business at home is treated as Residential

Payment & Security

Payment methods

Your payment information is processed securely. We do not store credit card details nor have access to your credit card information.

KANG Industrial Magnetic Bender EB5216

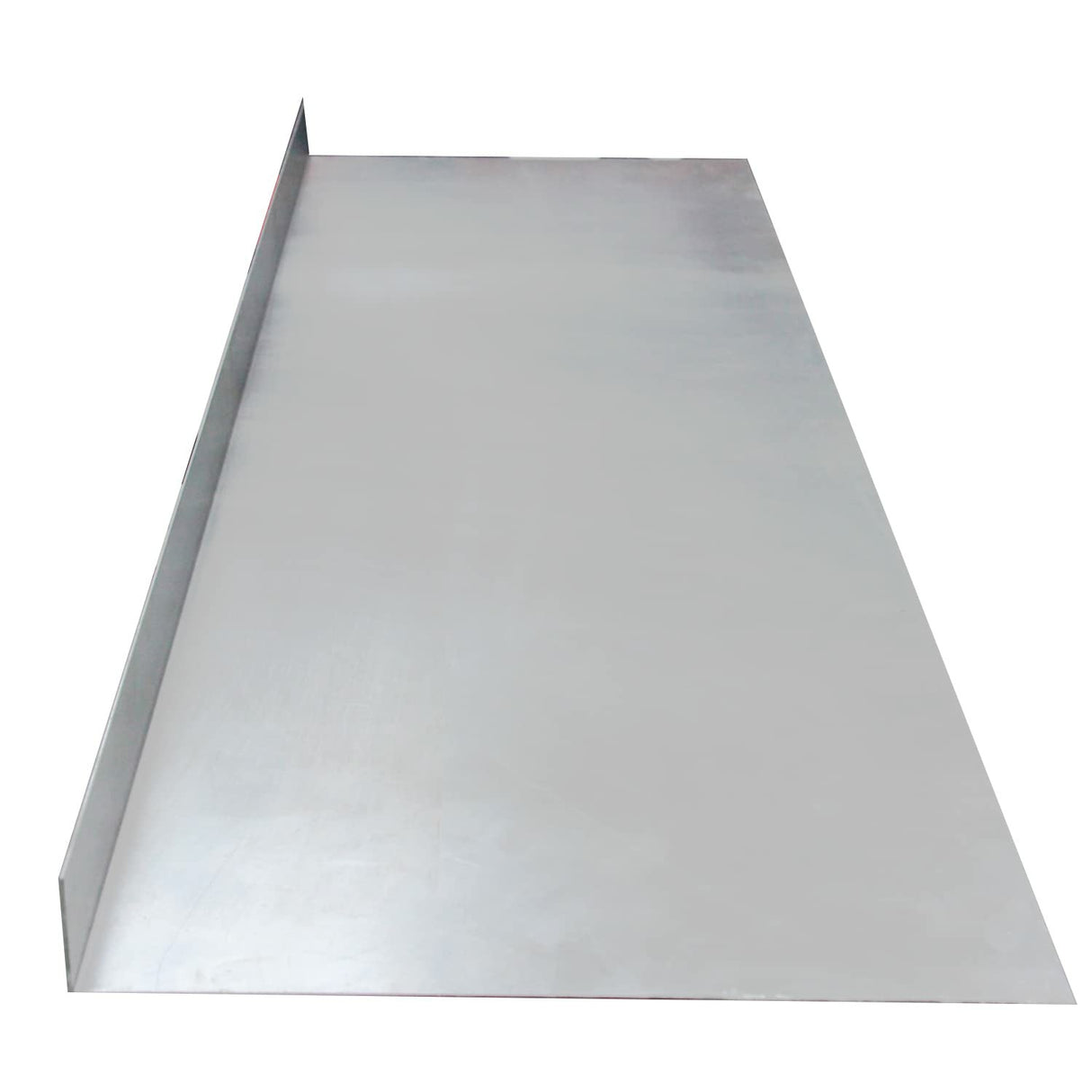

Revolutionize your sheet metal bending with the KANG Magnetic Panbrake EB-6116, an electromagnetic sheet bender built for precision and efficiency in fabrication workshops and trade environments. This innovative model features a generous 1550 mm working width and handles up to 1.6 mm mild steel, perfect for forming boxes, pans, and custom profiles without the limitations of traditional clamps. it delivers 8 tonnes of clamping pressure via a powerful electromagnetic system, with centerless hinges for even load distribution and a replaceable clamping bar for versatile shapes like round or square tubes.

Magnetic Clamping Bender Innovation for Effortless Setup. The 8-tonne electromagnetic system secures workpieces instantly without mechanical clamps, enabling distortion-free bends on thin sheets—ideal for Aussie fabricators in HVAC or signage shops, reducing setup time compared to conventional pan brakes and minimizing marks on delicate materials like aluminum or brass.

Versatile Material Handling Sheet Metal Bender. Excels with 1.6 mm capacities for mild steel and non-ferrous metals, plus stainless options, with adjustable back gauge and depth settings for infinite profiles—ideal for regional fabricators tackling HVAC ducts or automotive panels without tool changes, offering more flexibility than segmented models for curved or irregular bends.

Precision and Repeatability. Equipped with a back gauge, bend angle gauge, and scaled stroke angle control for consistent, accurate bends—reducing errors and saving time on production runs.

Unlimited Box Depth. The open-span design allows for the formation of boxes of virtually unlimited depth, overcoming the geometric restrictions of traditional panbrake folders.

Enhanced Safety and Productivity. Foot pedal control allows hands-free loading/unloading for safer, faster operation, improved electronics ensure consistent clamping—vital for solo operators in high-volume Down Under sites, minimizing fatigue and boosting output on repetitive jobs like box forming.

Features

Runs on 240V single-phase power

15500 mm length with a max. 1.5 mm mild steel bending capacity

No limitation to the depth of the box, open-end design

8-tonne pressure across the entire beam

Blade gap adjustment on clamping bars

Scaled stroke angle control lets you make repeatable bends

Different clamping bars

Suitable for HVAC shops, industrial art shops, and sheet metal fabrication shops

Could make enclosed boxes, triangles, etc.

Could bend a variety of materials, mild steel, stainless steel, aluminum plate, etc.

Different sizes available, EB4816, EB4816B, EB5216, EB9816

Specifications

| SKU | 173411 |

| Model | EB-6116 |

| Max. capacity (mild steel) | 1550x1.5 mm |

| Clamping force | 8 Tonne |

| Duty cycle | 30% |

| Back gauge | 640 mm |

| Nominal current | 6 Amp |

| Power motor | 2.5 kW |

| Protection | Thermal cut-out 70℃ |

| Bending edge length | 1620 mm |

| Distance between lifters | 1570 mm |

| Packing size | 176x112x38 cm |

| N.W./G.W. | 183/260 kg |

Shipping

1. The freight cost for orders Excludes Remote Areas as well as some rural and out lying areas. Our service executive shall contact you shortly after you place orders if you are in a remote areas. To obtain the shipping rates applicable to your address.

2. Standard freight charges do NOT include lifting off (unloading) from transport delivery vehicles where the total weight of goods exceeds 50kg, If you are unable to provide appropriate lifting please contact us for a quote on delivery that includes unloading.

3. Residential delivery for heavy package (Over 30kg) would have extra cost, you will be contacted with the Fee, or we deliver package to nearest fright depot.

4. If you need to cancel a purchase after the product has been dispatched, please note that the postage fee may not be refundable. Additional postage fees may apply for re-delivery or re-direction requests.

5. Buyers must agree with the above postage and handling terms before purchase. Thank you very much for your kind understanding.

Returns

1. 10 Day acceptance period from date of delivery. Damage claims and order discrepancies will not be accepted after this time.

2. You must obtain a KANG Industrial issued RGA number PRIOR to returning any materials.

3. Please ensure returned goods are well packaged and include the parts/invoice as requested

4. Altered items are not eligible for return.

5. Buyer is responsible for all shipping charges.

6. We reserve the right to charge a minimum 15% restocking fee and in addition charge for "making good" any damaged or used items returned including items damaged in transit.

Warranty

1. KAKA Industrial provides 12 months warranty for this product from the date of purchase.

2. Please note that this warranty does not apply to defects due directly or indirectly to misuse, abuse, alterations, lack of maintenance or consumable parts.

3. The original end-user must give written notice to Seller of any suspected defect in the Goods prior to the expiration of the warranty period.