CNC Sheet Metal Folding Machine TFM3100x2E, Sheet Folder for 3100x2.0 mm Mild Steel Plate, Electric Folding Machine

CNC Sheet Metal Folding Machine TFM3100x2E, Sheet Folder for 3100x2.0 mm Mild Steel Plate, Electric Folding Machine is backordered and will ship as soon as it is back in stock.

Couldn't load pickup availability

Delivery and Shipping

Delivery and Shipping

Standard freight charges do NOT include lifting off (unloading) from transport delivery vehicles where the total weight of goods exceeds 50kg, If you are unable to provide appropriate lifting please contact us for a quote on delivery that includes unloading.

Regional Australia address many need extra shipping cost

Business at home is treated as Residential

Payment & Security

Payment methods

Your payment information is processed securely. We do not store credit card details nor have access to your credit card information.

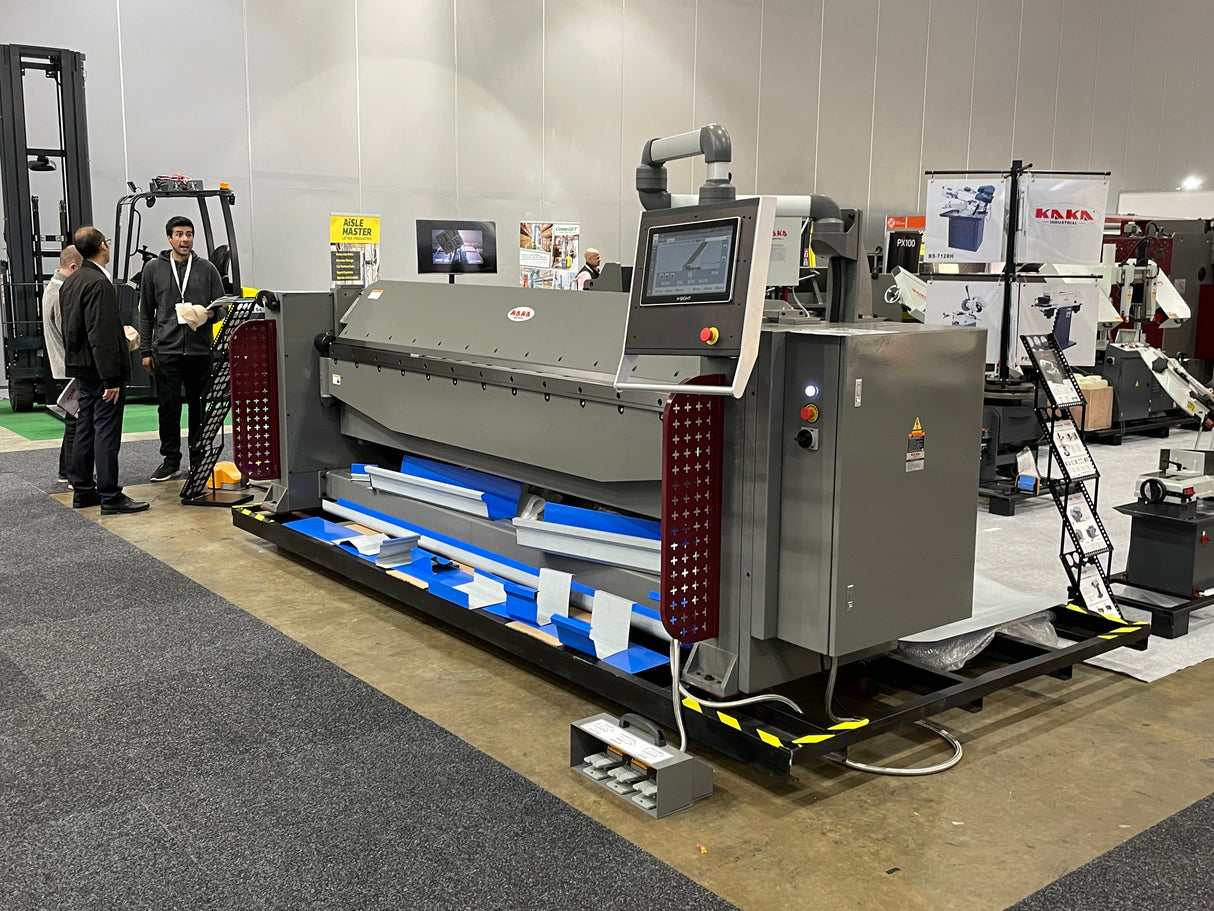

CNC Sheet Metal Folding Machine

The KANG CNC Folding Machine TFM3100x2E is a high-precision CNC folding machine designed for industrial-scale metal fabrication. This folder is optimised for handling large sheets with exceptional speed and ergonomic ease, making it a premium choice for professional workshops. The folding machine TFM3100x2E is built with a heavy-duty, all-welded steel frame to ensure maximum stability and long-term accuracy. It is an all-electric machine, which eliminates the maintenance and noise associated with hydraulic systems while offering significant energy savings.

Versatile for Common Materials Folding Handles up to 2.0 mm mild steel over 3.1 m length—suits everyday sheet metal work like flashings, ducting, trailers, gates, and architectural panels without switching machines.

Unmatched Ergonomics & Labour Savings Folding Machine. Because the bulk of the sheet rests on the back gauge table during the fold, a single operator can easily handle large, heavy sheets that would typically require two or three people on a standard press brake. This reduces fatigue and the risk of workplace injuries.

Precision Folding with "Sensitive" Materials. Australia’s architectural and signage industries often work with pre-painted or polished stainless steel. The KANG TFM3100x2E folding action involves significantly less friction than a press brake, meaning it leaves virtually no marks or scratches on sensitive surfaces. This eliminates the need for protective films or secondary polishing.

Rapid Setup for Short Runs. With the CNC control, an operator can go from a drawing to a finished part in minutes. The "Quick Tool Locking" system and the optional Combi Beam mean tool changes are measured in seconds, not minutes. This is perfect for "job shops" that handle a high variety of small-batch custom orders.

Low-Noise Operation. The all-electric drive system is ideal for workshops located in mixed-use or noise-sensitive areas. It consumes power only when actually moving and operates at a very low decibel level. Furthermore, the lack of hydraulic oil removes the risk of leaks and the cost of oil disposal.

Operator-Friendly & Safe. Material stays flat during folding (no flipping large sheets), back gauge ball transfers ease positioning, and the movable foot switch lets one person handle big parts—reducing fatigue and injury risk in busy workshops.

Features

Fully CNC Control, HMI-friendly operation

Max. bend 2mm thick plate at the full width, 3100mm width

Up to 2000 programs of storage, meet different bending requests

Design the bending on the touch screen immediately

The brake motor for clamping and bending, the machine will stop immediately at a pre-set angle

Bend Gutter, Drip Edge, CAP, Bump, etc.

Ideal For:

Roofing & Flashing Manufacturers: Precision folding of long 3.1 m sections.

Commercial Kitchen Fabricators: High-quality stainless steel work without surface marking.

Switchboard & Cabinet Makers: Complex box-and-pan folding with the Combi Beam system.

Signage Industry: Easy handling of large-format aluminium sheets

Specifications

| SKU | 173351 |

| Model | TFM3100x2E |

| Bending mild steel | 2.0 mm |

| Bending stainless steel | 1.2 mm |

| Bending width | 3100 mm |

| Max. bending angle | 0-135 degrees |

| Beam opening height | 125 mm |

| Min. reverse bend | 12.7 mm |

| Max. table back gauge distance | 1220 mm |

| Min. table back gauge distance | 12.7 mm |

| Back gauge repeatability | 0.1 mm |

| Back gauge table height | 910 mm |

| Main motor | 3.0 kW |

| Servo motor for the back gauge | 1.5 kW |

| Clamping motor | 1.1 KW |

| N.W./G.W. | 4280/4465 kg |

| Packing size | 434x201x160 cm |

Shipping

1. The freight cost for orders Excludes Remote Areas as well as some rural and out lying areas. Our service executive shall contact you shortly after you place orders if you are in a remote areas. To obtain the shipping rates applicable to your address.

2. Standard freight charges do NOT include lifting off (unloading) from transport delivery vehicles where the total weight of goods exceeds 50kg, If you are unable to provide appropriate lifting please contact us for a quote on delivery that includes unloading.

3. Residential delivery for heavy package (Over 30kg) would have extra cost, you will be contacted with the Fee, or we deliver package to nearest fright depot.

4. If you need to cancel a purchase after the product has been dispatched, please note that the postage fee may not be refundable. Additional postage fees may apply for re-delivery or re-direction requests.

5. Buyers must agree with the above postage and handling terms before purchase. Thank you very much for your kind understanding.

Returns

1. 10 Day acceptance period from date of delivery. Damage claims and order discrepancies will not be accepted after this time.

2. You must obtain a KANG Industrial issued RGA number PRIOR to returning any materials.

3. Please ensure returned goods are well packaged and include the parts/invoice as requested

4. Altered items are not eligible for return.

5. Buyer is responsible for all shipping charges.

6. We reserve the right to charge a minimum 15% restocking fee and in addition charge for "making good" any damaged or used items returned including items damaged in transit.

Warranty

1. KAKA Industrial provides 12 months warranty for this product from the date of purchase.

2. Please note that this warranty does not apply to defects due directly or indirectly to misuse, abuse, alterations, lack of maintenance or consumable parts.

3. The original end-user must give written notice to Seller of any suspected defect in the Goods prior to the expiration of the warranty period.