KANG INDUSTRIAL WPC-1000 Chuck, Suit WP-1000 Welding Positioner

KANG INDUSTRIAL WPC-1000 Chuck, Suit WP-1000 Welding Positioner is backordered and will ship as soon as it is back in stock.

Couldn't load pickup availability

Delivery and Shipping

Delivery and Shipping

Standard freight charges do NOT include lifting off (unloading) from transport delivery vehicles where the total weight of goods exceeds 50kg, If you are unable to provide appropriate lifting please contact us for a quote on delivery that includes unloading.

Regional Australia address many need extra shipping cost

Business at home is treated as Residential

Payment & Security

Payment methods

Your payment information is processed securely. We do not store credit card details nor have access to your credit card information.

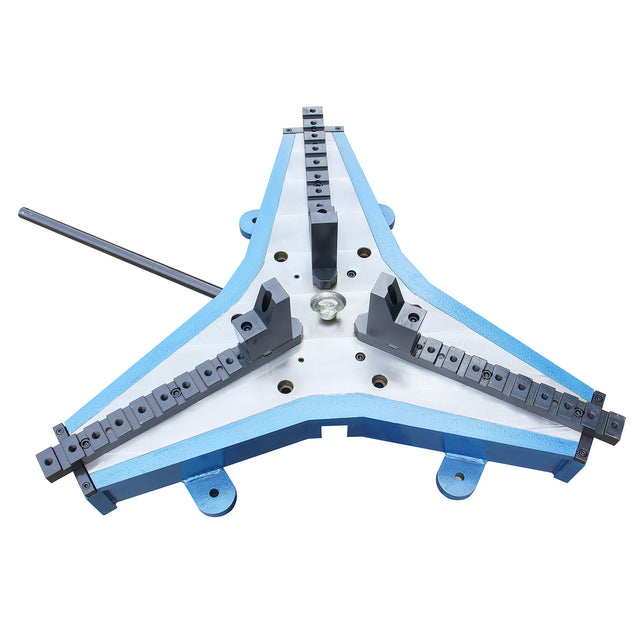

Welding Chuck, 3-Jaw Self-Centering Chuck

The KANG WPC-1000 is a professional 3-jaw self-centering welding chuck designed specifically as an accessory for welding positioners, rotary tables, and manipulators. It securely grips round, tubular, or near-round workpieces (pipes, flanges, shafts, cylinders, etc.) during rotation for precise MIG, TIG, or stick welding. The self-centering mechanism ensures fast, accurate clamping with minimal setup time, while the reversible jaws allow both internal and external gripping.

Versatile Clamping Chuck for Round Workpieces. Wide Ø200–1000 mm range handles small pipes to large flanges/cylinders common in Aussie mining, irrigation, structural steel, and oilfield fabrication – one chuck covers most jobs without multiple purchases.

Fast Setup & Changeover. Self-centring 3-jaw design grips instantly and accurately; short changeover times boost productivity in busy workshops or when switching between pipe sizes on the same positioner.

Lightweight & Positioner-Friendly. Low net weight reduces strain on welding positioner motors, bearings, and drives.

Improved Weld Quality on Rotated Parts. Secure, centred clamping ensures smooth, vibration-free rotation for consistent circumferential welds, better penetration, less distortion, and cleaner results on pipes/flanges.

Internal & External Gripping Flexibility. Reversible jaws allow clamping inside bores (e.g., pipe IDs) or outside diameters, essential for welding flanges to pipes or internal root passes.

Durable in Harsh Environments. Built tough for welding spatter, heat, and dust typical in mining, rural, or coastal workshops; reliable performance reduces downtime.

Specifications

Jaws: 3-jaw self-centering (reversible for ID/OD clamping)

Clamping Range: Ø200 mm – Ø1000 mm (internal & external)

Features: Self-centering for quick setup, lightweight design, includes a set of standard claws/jaws

Applications: Pipe, flange, cylinder, and round workpiece welding on positioners

Build: Robust for welding use (high current compatible when paired with positioners), low weight for versatility

Mounting: Standard bolt pattern for positioner tables WP-1000 or WP-2000

Shipping

1. The freight cost for orders Excludes Remote Areas as well as some rural and out lying areas. Our service executive shall contact you shortly after you place orders if you are in a remote areas. To obtain the shipping rates applicable to your address.

2. Standard freight charges do NOT include lifting off (unloading) from transport delivery vehicles where the total weight of goods exceeds 50kg, If you are unable to provide appropriate lifting please contact us for a quote on delivery that includes unloading.

3. Residential delivery for heavy package (Over 30kg) would have extra cost, you will be contacted with the Fee, or we deliver package to nearest fright depot.

4. If you need to cancel a purchase after the product has been dispatched, please note that the postage fee may not be refundable. Additional postage fees may apply for re-delivery or re-direction requests.

5. Buyers must agree with the above postage and handling terms before purchase. Thank you very much for your kind understanding.

Returns

1. 10 Day acceptance period from date of delivery. Damage claims and order discrepancies will not be accepted after this time.

2. You must obtain a KANG Industrial issued RGA number PRIOR to returning any materials.

3. Please ensure returned goods are well packaged and include the parts/invoice as requested

4. Altered items are not eligible for return.

5. Buyer is responsible for all shipping charges.

6. We reserve the right to charge a minimum 15% restocking fee and in addition charge for "making good" any damaged or used items returned including items damaged in transit.

Warranty

1. KAKA Industrial provides 12 months warranty for this product from the date of purchase.

2. Please note that this warranty does not apply to defects due directly or indirectly to misuse, abuse, alterations, lack of maintenance or consumable parts.

3. The original end-user must give written notice to Seller of any suspected defect in the Goods prior to the expiration of the warranty period.